- 09 Nov 2024

- Print

- DarkLight

- PDF

Packaging Guidelines

- Updated on 09 Nov 2024

- Print

- DarkLight

- PDF

Overview

This article shares insights on the packaging guidelines for your shipments. During packing, make sure to consider the following factors while choosing the packaging material:

- Dimensions: Helps in selection of appropriate size of boxes/flyers. Minimize inventory & cost

- Weight: Optimize for the minimum strength required for box. Ensures safety of item

- Fragility: Helps select appropriate box strength. Helps in optimizing the cushioning.

- Physical State: Identifies the need for any special requirements for the protection of item.

In this section

- Selection of Boxes

- Selection of Flyers / Boxes

- Packing an item

- Internal packing material vs functionality

- Leaking Proofing

- Sealing of Shipment

- Shipment Labelling

- Special handling labels

- Product categories

Selection of Boxes

Material

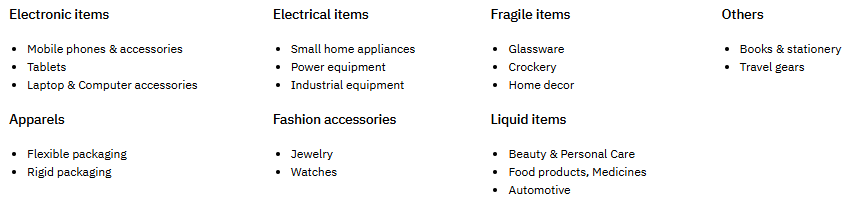

- Use corrugated boxes of 3 ply for products below 4Kg and not fragile.

- Use corrugated boxes of 5 ply for products above 4Kg and fragile.

- Use tamper evident boxes for high value items (Cost above Rs. 7000).

- Ensure the material used can withstand the required edgecrush and burst factor loads.

- Optimize the size of the boxes as per the product dimensions.

- The box should not be too small or too big for the item shipped. An optimum size box should be chosen.

- Inspect the box for holes, tears, crushed edges and sturdiness. Avoid poor quality boxes for the safety of the item shipped.

Size

- Optimize the size of the boxes as per the product dimensions

- The box should not be too small or too big for the item shipped. An optimum size box should be chosen.

Quick Check

- Inspect the box for holes, tears, crushed edges and sturdiness. Avoid poor quality boxes for the safety of the item shipped.

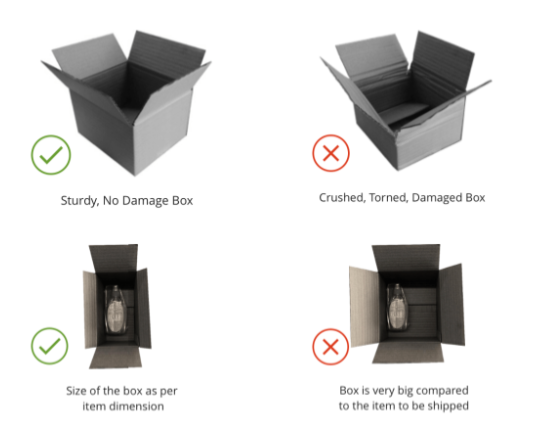

Selection of Flyers / Polybags

Flyers are quick and handy in packing of flexible items such as apparels or can be used as an added protection for the safety of the shipment from external fluids, tampering etc.

Material

- Choose 60-80microns hotmelt glue adhesive LDPE polybags

- Use tamper evident polybags for high value items (Cost above Rs.7000)

Quick Check

- Inspect the polybag for any damages

- Ensure the opening is sealed properly after the packing of item

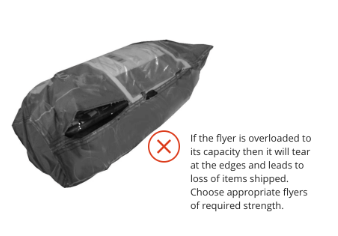

Packing an item

Packing an item involves leak proofing, cushioning, placing of the item and filling of the voids in the box. Enough cushioning needs to be provided to ensure no loads are transferred to the item.

Material

- Bubble Wrap

- Foam sheets

Internal packing material vs functionality

Leaking Proofing

Leaking Proofing

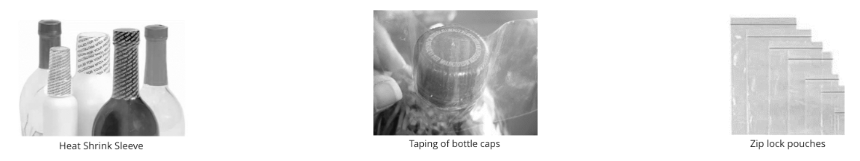

Liquid products need to be made leak proof before cushioning or packing. Common leak proofing techniques are mentioned below.

Material

- Heat shrink sleeves

- Taping of bottle caps

- Zip lock or leak proof pouches

Sealing of Shipment

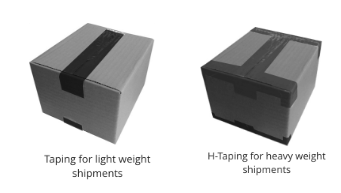

Sealing ensures that the properly packed item is secured and intact inside the box throughout the journey of the shipment.

Tape

Tape

- Use Pressure Sensitive Tapes such as BOPP

Locations

- Seal the center seam of the top and bottom of the box

- For heavy shipments, apply H-Taping by sealing both the center and edge seams on the box

Shipment Labelling

Proper labeling is crucial for faster and safe handling of the shipment in reaching the intended destination.

Essential Data

- Barcode height (min. size : 8 mm)

- Waybill number and Barcode (min. size : 8 MIL, 1MIL= 0.2032mm)

- Order number and Barcode (min. size : 8 MIL, 1MIL= 0.2032mm)

- Consignee address (min. font size: 8pts, Calibri body)

- Return address (min. font size: 8pts, Calibri body)

- Retail/Tax Invoice

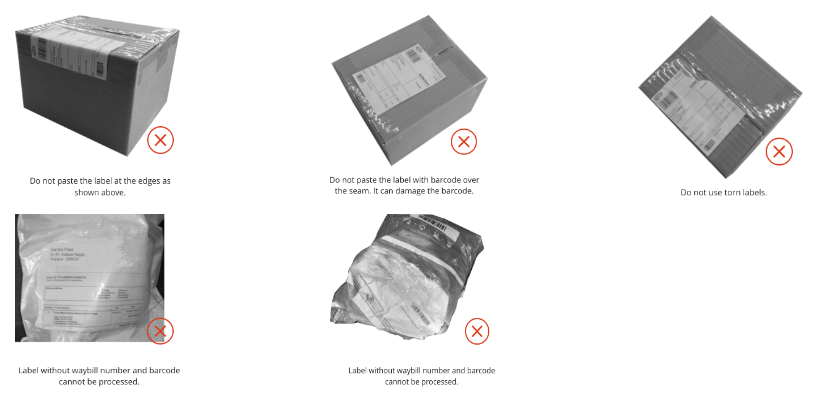

Location of Label

- Paste the label on a seamless flat face of the box/flyer

- Paste the label away from seams or edges of the box

- Readability of barcode is important for faster and correct processing of shipments

- In flyers/polybags, all the essential data on labels should be visible and the label should be placed flat

- The pocket containing the label in flyer should be taped at the opening to avoid the loss of label

- Thermal printed labels are strongly recommended over regular labels.

What not to do?

Special handling labels

Special handling labels helps in communicating the necessary information for appropriately handling the shipment.

Common Categories

- Fragile

- Perishables

- Dangerous goods

- Package orientation

- Keep dry

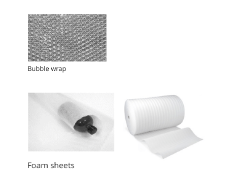

Product categories

Special handling labels helps in communicating the necessary information for appropriately handling the shipment.